Home > Semiconductors & Electronics > Automation > Robotics > Robot End-Effector Market

Robot End-Effector Market Analysis

- Report ID: GMI4286

- Published Date: Aug 2019

- Report Format: PDF

Robot End-Effector Market Analysis

The welding guns contribute to a major part in the robot end-effector market due to the increasing use of welding robots in the automotive industry. Manufacturers are implementing them to cut down the costs of direct labor, reduce the process time, and conserve the materials. Furthermore, the welding robots provide benefits such as a safer work environment, no break in production, consistent cycle times, and others, enabling their demand in the manufacturing industries. NIMAK, a robot equipment manufacturer has witnessed considerable growth in the robot welding gun manufacturing in China for companies such as Audi and Volkswagen.

Grippers are largely used in manufacturing processes for material handling applications such as picking up a workpiece. The growing advancements in the robot’s industry are bringing in more capable grippers for specific applications such as robot grippers with flexible fingers, grain-filled flexible ball, and others. The grain-filled flexible ball contains a latex balloon, which sucks in the air from the balloon and transforms into a rigid shape holding the given object without damaging it.

The robot end-effector market is gaining traction from the assembly applications. Assembly robots are largely used to increase the production capabilities in manufacturing companies as these robots significantly increase consistency and speed of the production lines. The assembly applications of end-effector include the production lines of automotive and mechanical components such as pumps, motors, gearboxes, engine components, and others. These robots provide an effective way to apply the adhesives and sealants with precision and can handle intricate parts eliminating human errors. Various developments such as the introduction of six-axis robots with greater flexibility of movements will further propel the growth of the robot end-effector market for assembly applications.

Material handling robots use end-effectors for lifting, transferring, or arranging the materials, components, and others from one location to another. The manufacturers are increasingly adopting these robots as they can automate unsafe, repetitive, and tedious tasks such as material handling in hazardous environments. Companies are developing these robots with higher payload capacity.

The automotive industry is expected to be a major segment deploying the robot’s technologies to improve productivity and quality of products. The automotive manufacturers are increasingly adopting robots to improve work efficiency and reduce warranty costs. These robots are being used for spot welding, painting, assembly, and other automotive operations. In addition, the robots minimize the risks involved by performing dangerous and difficult jobs.

Automakers including Ford Motor Company, TATA Motors, Hyundai, and others, are significantly using these robots for their automotive production to increase the production capacities and cater to the high demand. In June 2019, Ford completed an upgrade of its Chicago plant with an investment of USD 1 billion. The company added 600 robots to this plant for welding, chassis movements, and other functions.

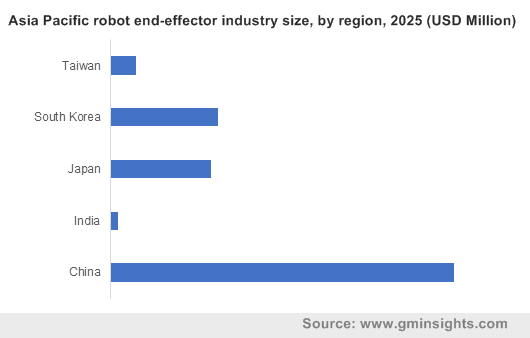

The Asia Pacific region will have rapid growth in the implementation of end-effectors owing to the deployment of a large number of robots in countries such as South Korea, China, Japan, and others. Japan, for instance, is the leading supplier in industrial robotics market and contributes to almost 55% of the industrial robot deliveries in 2017. Japan is also one of the major adopters of robots. According to the IFR, around 297,000 industrial robots were working in the country in 2017.

South Korea is another country highly contributing to the robot end-effector market demand in the Asia Pacific region. The country has a very high robot density compared to the global average amount. The strong developments in the electronics & electrical industry in the country is a key factor driving the growth of the robot’s industry in the country.