Home > Chemicals & Materials > Advanced Materials > Functional Materials > Refractories Market

Refractories Market Analysis

- Report ID: GMI3663

- Published Date: Jun 2019

- Report Format: PDF

Refractories Market Analysis

Refractories market based on form is segmented into bricks & shapes, monolithic and others. Bricks & shapes accounted for more than 55% of the total industry share in 2018. The bricks & shapes refractories are also called performed refractories and are basically utilized to form the floor tiles, arches and walls of various extreme temperature process equipment. Refractories shape and production depends primarily on the structure and size of furnaces or other services where refractories products are utilized. Only iron blast furnace needs refractories brick of varied shapes and sizes. However, other lining works are composed of standard refractories already available in the market. Special refractories shapes are developed to fulfill the specific lining criteria of each furnace such as stopper heads, arch tiles or over shapes.

Based on composition the market is classified into clay-based and nonclay-based refractories products. Clay based refractories market generated revenue close to USD 16 billion in 2018. Clay based refractories include mullite ceramics, fire clays, etc. They are generally produced as monolithics, preformed brick and also materials which are composed and solidified on-site. Clay based refractories also helps in developing light weight refractories in the form of blankets, vacuum cast shapes and fiberboards.

Based on type the market is divided into acidic, basic and neutral. Neutral type segment accounted close to 60% of the total industry share in 2018. Neutral refractories cannot be attacked by acid or basic slags and are thus the most preferred product type. Neutral refractories include graphite, chromites, zirconium carbide, silicon carbide, etc. While, graphite is less reactive than other materials, it is also used in metallurgical furnaces where oxidation can be controlled.

Refractories market based on manufacturing process is segmented into unformed, dry press, fused formed, fused cast and hand molded. Fused cast market size in terms of revenue was over USD 4 billion in 2018. The raw materials necessary for refractories in each manufacturing process are oxidized prior to melting by treating it with heat, to reduce oxygen content required for oxidizing molten refractories.

Refractories market based on end-user is segmented into iron & steel, non-metallic materials, non-ferrous metals and others. Iron & steel market size accounted close to 65% of the total industry share in 2018. Iron and steel requires refractories to be used in blast furnaces, basic oxygen making steel vessels, process gas heaters, troughs, electric arc furnace, torpedo ladles, etc. China has well established iron and steel market which represents as an important factor driving refractories production in the country.

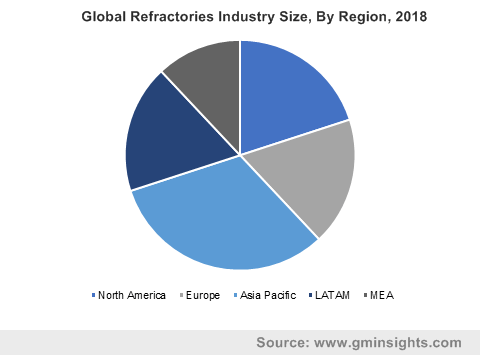

Asia Pacific led the overall market share and is likely to exhibit gains close to 4.0% CAGR by 2025. The growth of APAC market is largely driven by the growing production and research and development centers in the region. Japan, India and China are the leading contributors in iron & steel, non-ferrous and glass industries. Various industries are growing due to growing per capita expenditure of the population and rising urbanization in the region. These factors are anticipated to drive Asia Pacific refractories market size by 2025.