Home > Chemicals & Materials > Polymers > Industrial Polymers > Nitrile Butadiene Rubber (NBR) Powder Market

Nitrile Butadiene Rubber (NBR) Powder Market Analysis

- Report ID: GMI2480

- Published Date: Jun 2020

- Report Format: PDF

Nitrile Butadiene Rubber Powder Market Analysis

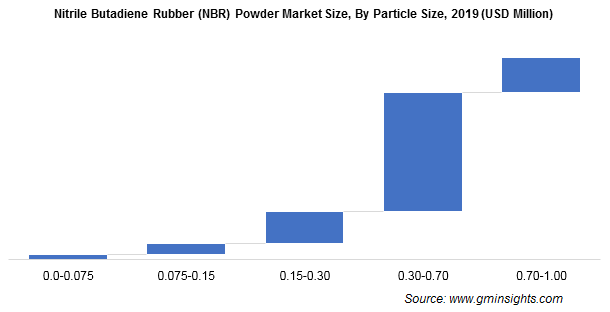

Nitrile butadiene rubber powder with particle size between 0.30 to 0.70 is likely to witness around 4.0% CAGR during the forecast spell owing to its wide application for PVC modification. Particle size of the powder plays a major role during the initial degradation stage. After empirical testing by various manufacturers, the maximum accepted size or diameter for NBR powder was set at 1 mm.

The required diameter of powder particles also varies according to the application. While manufacturing products for dry applications are finer and induce a higher friction coefficient, whereas the trend is reversed for oil-lubricated conditions such as couple plates. These factors will positively influence the nitrile butadiene rubber powder market penetration for various applications across several end-use sectors over the forecast period.

In 2019, cross linked NBR powder accounted for more than 50% of the nitrile butadiene rubber powder market share and is likely witness a significant growth from 2020 to 2026. Cross linked NBR powder is the most widely used grade in the segment that finds application in myriad end-user industries. Cross linked NBR grade is extensively used in soft PVC compound modification for calendaring processes. Some products manufactured from this grade include coated fabrics, hoses, cable covers, footwear soles, conveyor belts, crash pads, brake pads, linings, etc.

Superior properties such as higher tensile strength, flexural strength, elongation modulus and excellent dimensional stability, along with increasing end-use production rate and improving the final product surface will further support the NBR powder market across various end-use sectors.

PVC modification lead the application segment with over 45% share in nitrile butadiene rubber powder market in 2019. This is owing to wide usage of product in PVC modification. Addition of NBR powder to PVC imparts important characteristics to resultant compounds such as impact resistance, low temperature flexibility, chemical resistance, and superior mechanical properties. Thus, NBR-modified PVC products finds extensive usage in making a wide range of products including hoses, cable sheathings, automotive and other machinery parts, shoe soles, printing rolls, etc.

The typical blending ratio of PVC and NBR powder lies around 7:3 by weight, and the components retain their individual properties, enhancing the overall product quality. These blended polymers have excellent resistance to ozone, oil, and abrasion, while maintaining superior extrusion properties.

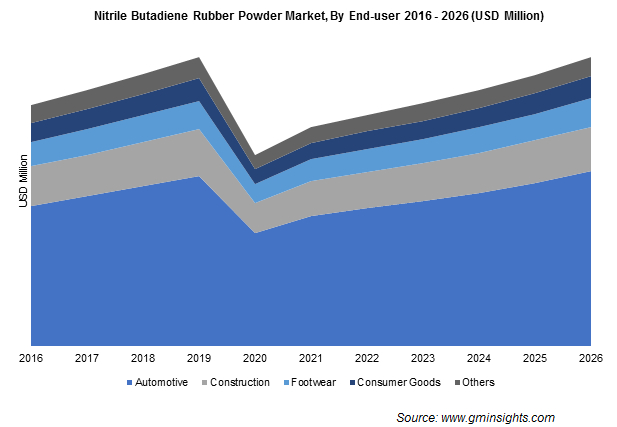

The automotive sector leads the NBR powder market as it installs various parts and components based on NBR powder blends. NBR powder is directly used in making friction materials for vehicle brake pads, linings, coupling plates, fuel pipes, as well as interior parts such as dashboards, steering wheels, panels, etc. This segment accounted for more than half of product volume in 2019 and is anticipated to grow with the significant rate during the coming years.

The construction sector will be another key end-user sector due to the need for NBR-blended wire insulation materials. The rising popularity of the product in providing heat and flame resistance will boost the nitrile butadiene rubber powder market segment in the coming years.

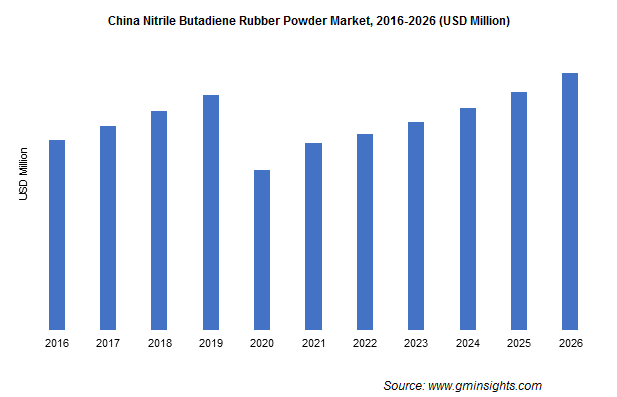

Asia Pacific will witness over 7.5% CAGR over the study timeframe owing to the vast number of industries present in the region. The region is anticipated to exhibit growth at the highest rate owing to the fast-developing countries such as China, South Korea, and India. Large number of small and unorganized players operate in Asia Pacific pose competition for product growth in the coming years.

PVC modification and frictional material sectors majorly account for demand for NBR powder in the region. Growth in the transportation sector in Asia Pacific is likely to be a key driving factor for the nitrile butadiene rubber powder market.