Home > Chemicals & Materials > Advanced Materials > Ceramic 3D Printing Market

Ceramic 3D Printing Market Analysis

- Report ID: GMI4385

- Published Date: Oct 2019

- Report Format: PDF

Ceramic 3D Printing Market Analysis

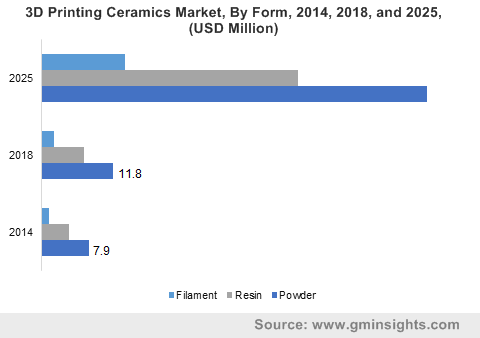

Resin forms provide flexibility in the additive manufacturing process and are ideal for making high resolution products. This segment will showcase considerable growth in the market and valued more than USD 7 million in 2018 owing to increasing usage of advanced resins into dental restoration applications. Developments of several technologies including MOVINGLight UV polymerization technology allow fabricated parts with up to 99% ceramic density after de-binding and sintering. This enables resin to be used in several applications including medical and electronics. Additionally, several industry participants, are launching new resins for additive manufacturing processes. For instance, in August 2018, Ackuretta Technologies, launched ceramic resin material for DLP 3D printers. This strategy enable company to enhance their presence in medical sector.

Powdered ceramics hold dominance in the ceramic 3D printing market with approximately two-thirds the volume share, owing to development of new ceramic powders that can be used in tooling and part manufacturing. These forms are recommended in powder/binder jet 3D printers and are relatively easy to use. Powdered ceramics are abundantly available at lower costs as compared to other product forms. Additionally, the excess powder waste in one additive manufacturing stage can be recycled. This enables the user to incur material losses, thereby further escalating demand.

Ceramic rapid prototyping is a popular process to develop and try out new designs before using expensive tooling. This segment was valued at more than USD 10 million in 2018 and enables manufacturers of large and complex parts to eliminate of the process of repetitive and expensive re-tooling during the manufacturing processes. Rapid prototyping is used in several biomedical and casting molds owing to excellent surface finish and dimensional accuracy of fabricated parts.

Part production application of ceramic 3D printing market analysis will showcase gains with more than 30% compounded growth in the future, owing to development of upgraded printers for several applications. Advancements in additive manufacturing further enable part manufacturers to achieve higher dimensional accuracy along with ease in producing complex parts. This in turn reduces overall manufacturing costs for intricate structures and complex shapes. Additionally, usage of several ceramic materials such as composite ceramics further contributed to enhanced mechanical properties of fabricated parts, thereby supporting product preferences.

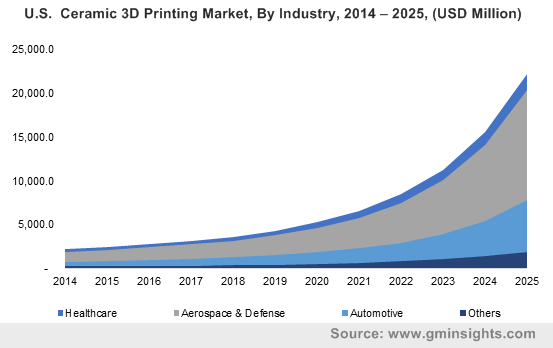

Aerospace & defense held more than 30% of the volume share in the industry and will grow substantially between 2019 and 2025 considering rising ceramic material adoption in commercial and military aircraft. Ceramic materials are lightweight as compared to metals and possess high thermal stability in adverse conditions. Ceramic structures are used in the aerospace industry as thermal barrier coatings in high temperature areas such as the primary engine, propeller, booster and other sections of the propulsion system. Additionally, 3D printed ceramic matrix composites (CMC) are integrated into landing systems to minimize the overall weight of the landing system while taking a higher impact force while maintaining core structure shape and stability.

Automotive ceramics was valued close to USD 7.5 million in 2018, owing to rising vehicle production in highly populated regions. Ceramic additive manufacturing enables auto part manufacturers to ease any design modifications owing to their ability to print new prototypes directly from updated design files saved on software platforms such as CAD-CAM. This provides opportunity for automotive manufacturers to increase manufacturing turnover, reduce cycle times and quickly produce key complex parts within the least time.

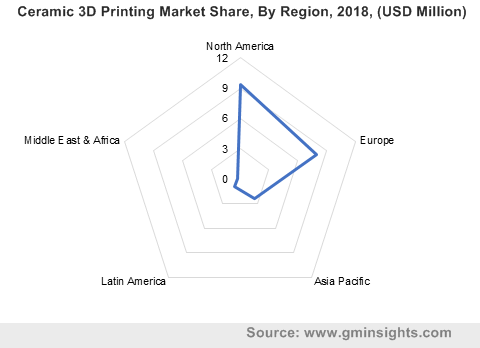

North America held its dominance in the ceramic 3D printing market with over 40% volume share owing to presence of several aircraft manufacturers in the region. Integration of ceramic fabricated parts in aircraft engines along with development of several new materials will further propel attractiveness. Rising popularity of low-weight designs and advanced stealth technologies in defense applications will employ additive manufacturing techniques to reduce the overall weight of aircrafts and enable a variety of design standards in the field. Lightweight characteristics would also reduce the overall carbon footprint through enhanced fuel efficiency.

Asia Pacific will showcase the fastest growth owing to rising electric vehicle production in the region and advent of smart technologies. The region accounted for about half of the total vehicle production across the globe in 2018. Additionally, rising aging population in several counties including China and Japan along with growing ceramic 3D printing applications in medical sector will provide lucrative opportunity for expansion.