Home > Chemicals & Materials > Polymers > Industrial Polymers > Polystyrene (PS) & Expanded Polystyrene (EPS) Market

Polystyrene (PS) & Expanded Polystyrene (EPS) Market Analysis

- Report ID: GMI2063

- Published Date: Oct 2018

- Report Format: PDF

Polystyrene & Expanded Polystyrene Market Analysis

Polystyrene led global polystyrene & expanded polystyrene market in 2017 and accounted for more than half of the total market share. The product has been used in refrigerator lining, packaging and construction industry. It is lightweight, cost effective and can be recycled conveniently. Its shatterproof characteristics and low conductivity makes polystyrene highly desirable in electrical insulation. Moreover, growing demand for disposable and reusable containers in food industry shall fuel product usage for packaging applications by 2025.

EPS is 98% air and the rest is composed of small, spherical EPS beads—made only of hydrogen and carbon. EPS has been the second-largest styrene derivative, after polystyrene. EPS is characterized by properties such as: rigidity, light weight and ideal thermal insulation. The segment shall witness substantial growth in the coming years, expanding at a CAGR of 4.6% due to its 100% recyclability, lightweight and compressive resistance. EPS applications will be significantly demanded in safety wear manufacturing such as helmets, as it provides superior shock resistance along with long time durability.

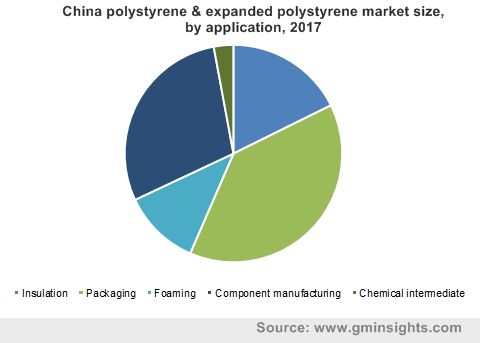

Packaging emerged as the leading application in the polystyrene & EPS market, accounting for over 30% share in 2017. PS and EPS are widely used in packaging of food, electronic appliances, retail items and consumer goods. They are preferred in packaging as it is light in weight and offers excellent insulation and weather resistance properties. However, the segment will observe moderate growth by 2025 due to increase in relative market share of other applications and several bans on plastic usage in food packaging application due to environmental issues.

Plastics have been extensively preferred over metals in automobiles in the recent years on account of easy moldability, superior impact strength, improved aesthetics, cabin insulation, scratch resistance and lightweight. An average car includes approximately 10-15% plastics of total car weight. All polystyrene & EPS components play a critical role in automobile manufacturing. The products can be found in a range of applications in this industry including: seating components, front and rear bumper cores, void fillers, roof liners, padding, housing brackets, head impact protection (head rests), side impact protection, pedestrian impact protection, knee bolsters or steering column hoods, boot spacers, sun visors, trunk liners, battery housing. The transportation sector is estimated to have a growth above 4% CAGR in global PS & EPS market by 2025.

In 2017, Asia Pacific held the highest share above 40% in global polystyrene & expanded polystyrene market. The region will observe similar trend in the coming years. In the same year, China had a robust share above 50% in the region, for the vast production capacities availability raw materials and robust industrialization, cost-effective manufacturing and the immense growth trends in the sectors including: consumer goods, transportation, electrical & electronics and construction are expected to support the regional growth.