Home > Chemicals & Materials > Advanced Materials > Functional Materials > Metal Injection Molding (MIM) Parts Market

Metal Injection Molding (MIM) Parts Market Analysis

- Report ID: GMI4392

- Published Date: Oct 2019

- Report Format: PDF

Metal Injection Molding Parts Market Analysis

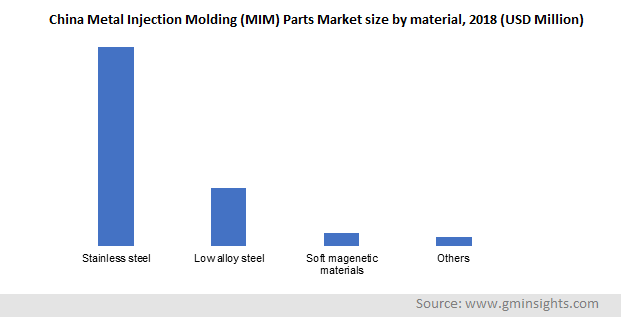

MIM parts can be manufactured from various metal powders namely low alloy steel, stainless steel, soft magnetic materials, tungsten-based materials and many more. Stainless steel holds the maximum metal injection molding parts market share of around 60% among all the other materials. MIM part achieves value added strength, high density along with corrosion resistance by using steel powders as feedstock in the manufacturing process. Moreover, low alloy steel also captures a comparatively significant chunk in the materials segment.

The material is used largely in the industry as a result of providing enhanced mechanical and corrosion resistance properties as compared to other materials such as carbon steel. Low alloy steels are generally utilized in firearms industry for manufacturing several guns as well as archery components. The material is also used in automotive sector for producing transmission & engine components and in industrial goods industry for producing various power and hand tools.

Metal injection molding parts are used in various sectors such as automotive, electronics, firearms, consumer goods, aerospace etc. Firearms industry is one of the promising end user sector of metal injection molding parts market growth. Almost all manufacturers of firearms use MIM technology to simplify the production process in a cost-effective way. Common parts in this industry includes trigger guards, bolt sleeves, floorplates, sight basis etc. The reason behind using MIM technology in firearms production is that the process is highly automated, which in turn saves labor cost as well as time.

Stretching U.S. defense budget as well as combat activities in the Middle East countries has been increasing the demand for small arms and guns, which in turn is expected to positively influence product consumption in the coming years. Beginning of Trump era has resulted in the increasing defense budget in the U.S., as administration has increased its focus towards military and defense sector. Aerospace and defense is the largest exporting industry in the U.S. generating a net revenue of over USD 85 billion in 2018. A rising defense industry in US and in other NATO countries is the key reason behind rising demand for MIM parts in production process of firearms.

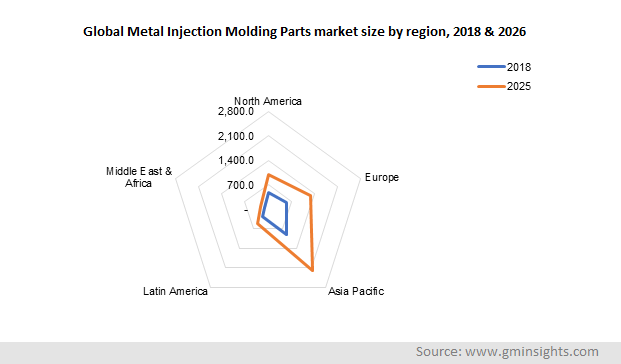

Asia Pacific has emerged as the highest growth avenue for metal injection molding parts market owing to presence of various emerging economies in the region and growing demand from various end user industries. The region’s demand is highly dependent on China, India and other developing economies. China constitutes around 40% of the total MIM parts demand in the region, majorly led by its flourishing electronics industry. The country has the world’s largest production base for electronic products accounting to around 30% of global total ICT products exports worldwide.

To be more specific, China is a hub for producing computers, mobile phones and other electronic gadgets. The country has been experiencing a double-digit growth in electronics industry. Apart from China, countries including Singapore, Taiwan and South Korea also make a large share in regional and global electronics industry, which triggers the demand for MIM parts in manufacturing these electronics products