Home > Industrial Machinery > Industrial Equipment > Metal Injection Molding Market

Metal Injection Molding Market Size

- Report ID: GMI2563

- Published Date: May 2018

- Report Format: PDF

Metal And Ceramic Injection Molding Market Size

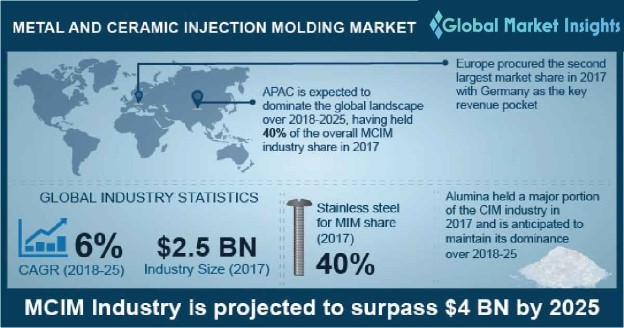

Metal And Ceramic Injection Molding Market size was over USD 2.5 billion in 2017 and will grow at a CAGR over 6% over the projected period.

Metal injection molding (MIM), & ceramic injection molding (CIM) are collaboratively called powder injection molding. Powder injection molding combines both material flexibilities based on powder metallurgy and design flexibility based on molding, which helps create metal and ceramic parts. This molding technology is used for manufacturing products of high strength, and complex structures, while providing an improved surface finish. Both metal injection molding and ceramic injection molding additionally impart a sophisticated production capacity than traditional molding processes. This molding process uses a mixture of ceramic or metal powders with polymer binders to produce parts that exhibit properties of plastic. The raw material used for metal injection molding or ceramic injection molding comprises around 60% of ceramic or metal powders while the remaining volume is the binder.

The metal and ceramic injection molding market is predicted to increase over the coming years, owing mainly to the growing demand among key end user applications for the size reduction of complex parts that need high-performance materials. The rising demand for small parts is also augmenting the metal and ceramic injection molding demand with various materials, particularly silicone and stainless steel. All these are used to manufacture miniature products in automotive components, aerospace components electronic components, and also healthcare devices that are useful in IV therapy, advanced drug delivery, vascular therapy, and invasive surgeries. Key factors such as growing demand for PIM parts in the healthcare industry is also expected to boost the global market during the forecast timespan. The quality and delivery of metal injection molding processors are guaranteed by several accreditations such as ISO 9002 and QS 9000, thereby increasing the product demand. Moreover, increasing demand from firearms in the defense industry, mostly in the U.S., will enhance the growth of the metal and ceramic injection molding market.

| Report Attribute | Details |

|---|---|

| Base Year: | 2017 |

| Metal And Ceramic Injection Molding Market Size in 2017: | 2.5 Billion (USD) |

| Forecast Period: | 2018 to 2025 |

| Forecast Period 2018 to 2025 CAGR: | 6% |

| 2025 Value Projection: | 4 Billion (USD) |

| Historical Data for: | 2013 to 2017 |

| No. of Pages: | 500 |

| Tables, Charts & Figures: | 642 |

| Segments covered: | Product, Application and Region |

The global MCIM market is majorly restrained by the limitations regarding the size and weight of the molded parts, coupled with high prices of material used for metal injection molding. Size limitation in metal injection molding processes shows major impact on the growth of global market. Due to the lack of space in MIM furnaces, the most suitable size of metal injection molded products is 10-15 mm. The material required for metal injection molding is a part metal powder, and part binder. Usually, the prices of these materials is high, which in turn increases the prices of metal injection molded products, thereby showing a significant impact on the growth of metal and ceramic injection molding market.