Home > Chemicals & Materials > Advanced Materials > Aerospace 3D Printing Materials Market

Aerospace 3D Printing Materials Market Size

- Report ID: GMI4698

- Published Date: Jun 2020

- Report Format: PDF

Aerospace 3D Printing Materials Market Size

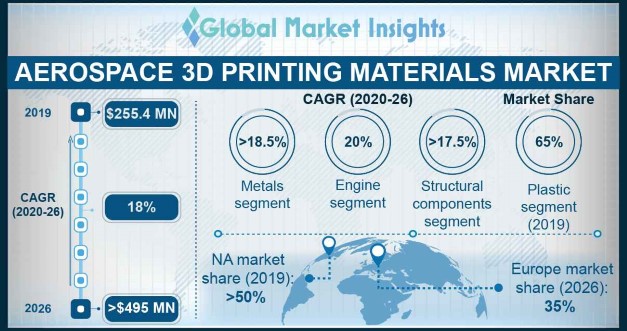

Aerospace 3D Printing Materials Market size surpassed USD 255 million in 2019 and is estimated to grow at a CAGR of over 18% between 2020 and 2026.

3D printing is widely used in the aerospace industry to manufacture low-volume complex parts. Aerospace 3D printing materials vary from PEI to engineering-grade PEEK, with their use in the production of structural parts and door panels. The metal including, titanium and aluminum play key role in aerospace 3D printing industry to manufacture critical components such as engine turbine blades, brackets, etc.

Factors such as, advent of low-cost carriers and increasing air passengers are key factors propelling the aerospace industry. Growing concern for fuel-efficient aircrafts by using lightweight parts has substantially driven the adoption of 3D printing technology. The ability to manufacture functional parts with intricate designs and defined aerodynamic properties in short runs is possible using AM. It enables to achieve a weight reduction of 40-60% that significantly saves the material costs.

The 3D printing metals enables the production of more efficient engine, turbine, and lightweight parts that reduces the fuel consumption, thereby reducing CO2 emissions. Moreover, AM provides maximum functionality to be combined into a few parts as possible.

| Report Attribute | Details |

|---|---|

| Base Year: | 2019 |

| Aerospace 3D Printing Materials Market Size in 2019: | 255.4 Million (USD) |

| Forecast Period: | 2020 to 2026 |

| Forecast Period 2020 to 2026 CAGR: | 18.1% |

| 2026 Value Projection: | 498.1 Million (USD) |

| Historical Data for: | 2016 to 2019 |

| No. of Pages: | 285 |

| Tables, Charts & Figures: | 444 |

| Segments covered: | Material, Application, Aircraft Parts, End-use, Region |

| Growth Drivers: |

|

| Pitfalls & Challenges: |

|

Leading companies such as Boeing, Airbus, and Lockheed Martin have incorporated aerospace 3D printing materials in the production of functionally integrated lightweight prototypes and structural parts. To enhance the production process of aircraft, these companies are signing partnership agreements with AM companies to leverage the benefits of aerospace 3D printing materials.

High materials costs coupled with stringent certification standards by Federal Aviation Administration (FAA) are likely to limit the aerospace 3D printing materials market demand. Further, the outbreak of global coronavirus pandemic has led to temporary closure of aerospace manufacturing industry leading to temporary shutdown of the production facilities.