Summary

Table of Content

Purging Compound Market

Get a free sample of this report

Form submitted successfully!

Error submitting form. Please try again.

Thank you!

Your inquiry has been received. Our team will reach out to you with the required details via email. To ensure that you don't miss their response, kindly remember to check your spam folder as well!

Request Sectional Data

Thank you!

Your inquiry has been received. Our team will reach out to you with the required details via email. To ensure that you don't miss their response, kindly remember to check your spam folder as well!

Form submitted successfully!

Error submitting form. Please try again.

Purging Compound Market Size

Global Purging Compound Market size was valued over USD 300 million in 2016 and is set to exceed 14 kilo tons by 2024. Shifting manufacturer preference to reduce machine downtime, curb raw material wastage and lower cleaning costs coupled with rapid industrialization particularly among automotive, healthcare, consumer goods, electronics and packaging sectors will stimulate the industry growth.

Eliminating degraded residues, un-melted resins, foreign contaminants, true gels, moisture, un-dispersed additives & modifiers, and air bubbles from machine barrels are among the key features driving the purging compound market demand. Corporate Average Fuel Economy (CAFE) guidelines to produce less fuel consuming automobiles will foster industry growth. A 10% drop in overall weight by effective cleaning results in about 5% to 7% fuel saving in an automobile. Furthermore, the reduced weight also helps control CO2 emission levels over the vehicle life cycle.

To get key market trends

Ensured quality and safety along with effective plastic resin & contamination removal from screws & barrels of the equipment in several processes will fuel product penetration. Prevention from resin mixture during plastic and color replacement along with optimum maintenance of components will propel the purging compound market growth.

Emergence of extrusion utilizing purging compounds in the packaging industry will drive the growth prospects for the purging compound market over the forecast period. Extrusion process helps in differentiating plastics from different substrates for the equipment cleaning purposes. Further, increasing application in several packaging industries including liquid packaging, flexible packaging, and medical packaging is expected to generate high product demand.

Purging Compound Market Report Attributes

| Key Takeaway | Details |

|---|---|

| Market Size & Growth | |

| Base Year | 2016 |

| Market Size in 2016 | 300 Million (USD) |

| Forecast Period 2017 - 2024 CAGR | 8.6% |

| Market Size in 2024 | 600 Million (USD) |

What are the growth opportunities in this market?

Rising preference for cost effective scrap removal solutions to control carbon deposition and corrosion particularly in chemical industry has positively enhanced product demand. Changeable raw material costs owing to high dependency on crude oil prices may impact purging compound market price trend.

Purging Compound Market Analysis

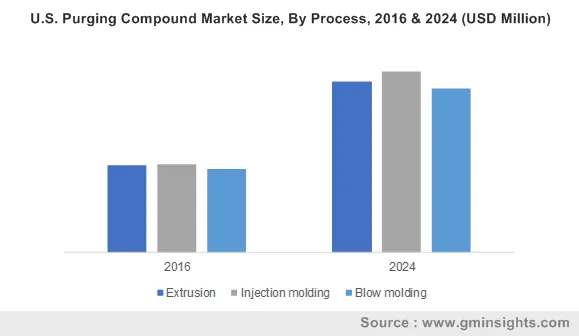

Extrusion is projected to witness growth rate 7% through 2024. High product requirement for extrusion due to advantages including faster color & material changes and ease in carbon removal will enhance industry. Improved processing among comprehensive thermoplastics including GPPS, PP, PC, PA and ABS is the key factor supporting the purging compound market share.

Injection molding process segment was worth of USD 109 million in 2016. Injection molding extensively use these compounds while changing resin, color or removal of black specks. Easy color changeability without demounting equipment, thus gaining optimum results are key factors fueling product demand. High cleaning accuracy in several engineering components will further enhance product penetration.

Learn more about the key segments shaping this market

Blow molding has been observing significant growth in the industry. Increasing demand for the mass production of several injection molded components from end-use industries including automotive will enhance the purging compound market share.

Mechanical purging is projected to surpass USD 400 million by 2024. Efficient removal of polymer deposit by utilizing high viscosity plastics from screws and barrels will enhance the product demand. Increasing demand for plastic processing units due to manufacturing industry expansion will drive the purging compound market growth.

Chemical/foaming was valued over USD 90 million in 2016 as it is considered as the most common product used in plastic processing apparatus. High foldability rate making the scrap to repeatedly be used to remould parts is expected to improve product usability.

Liquid form is anticipated to observe a growth rate of more than 7.5% through 2024 due to increasing demand for the removal of all thermoplastics. The form is extremely effective for resin to resin and color to color changes to provide easy, quick, safe and cost-effective conventional processing. In addition, unique form properties including non-requirement of soaking and cracked acrylic resin inventory will drive the overall global purging compound market.

Granule form segment was worth of over USD 250 million in 2016. The form significantly limits the removal of certain contaminants including carbon build up from the extruder. It is effective for the treatment of several chemicals that are in a granule structure of ultra-high purity purges. Further, the form evolves as a crucial part in production of specialized cleansing materials and thereby boosting global purging compound market.

Automotive is anticipated to maintain its dominance over the forecast period owing to extensive adoption of lightweight and sustainable plastic materials in the form of equipment, films and fasteners components. Automotive industry will be valued over USD 130 million by 2024. Exclusive partnerships between OEMs and product manufacturers will benefit in industrial development in terms of supply chain efficiency. Furthermore, increasing initiatives by automakers to accommodate growing senior driver population by including safety features will boost the global purging compound market revenue.

Electronics sector held 8% of volume share in 2016. These product mixtures are used in a wide array of electronics applications including switches, sockets, enclosures, housings and semiconductors. Growing necessity for heat resistance, flame retardancy and enhanced serviceability in producing materials will drive the purging compound market segment.

North America registered over USD 100 million in 2016 with largest production share over the forecast period. This share is primarily credited to the large base of plastic processing units in the region. Increasing demand for plastics processing equipment is also expected to drive global purging compound market growth.

Asia Pacific is anticipated to grow at a rate over 7% from 2017 to 2024. The growth will be attributed to rapid industrialization contributing towards expansion of several industries including food & beverage, construction, automotive, petrochemicals and chemicals. As these composites is gradually used by these industries to decrease machine downtime and expand manufacturing efficiency, the growth of the end-use industries will continue to boost the global purging compound market sales.

Purging Compound Market Share

Global purging compound industry share is fragmented in nature with presence of large number of manufacturers and distributors across different regions. Major leading industry participants include

- Asahi Kasei Corporation

- VELOX GmbH

- Dyna-Purge

- Chem-Trend LP

- E. I. Du Pont de Nemours

The key industry players have adopted numerous growth strategies including new product launches, mergers & acquisitions, joint ventures, partnerships, innovation and technological advancements to strengthen their position.

For instance, in 2016, Chem-Trend acquired the Italian engineering and designing company Moulds Plus International’s business “Ultra Purge” to expand its thermoplastic processing portfolio.Other prominent players are

- 3M

- Purgex

- Magna Purge

- RapidPurge

- Reedy Chemical Foam & Specialty Additives

- CALSAK Corporation

- Formosa Plastics Corporation

- Dow Chemical

- Daicel Corporation

- Kuraray

- Clariant AG

- Ultra System SA

- Polyplast Muller GmbH

- Slide Products

Companies invest enormously in R&D operations to offer distinguished solutions to gain competitive advantage.

Industry Background

Rising number of plastic processing units on a global scale coupled with growing demand for purging compound, particularly in engineering thermoplastics will drive the product market size. Improved governmental regulations, commercialization and new product launches in several emerging economies including India, China, Thailand, South Korea and Brazil will further propel the global purging compound market expansion.

Increasing efficiency as compared to traditional cleaning approaches including purging with regrind along will drive industry development. Benefits of using the product include low manufacturing cost, less material waste, less scrap and reduced downtime. Thereby, these benefits positively impact industry growth over the forecast timeframe.

Global purging compound market report includes in-depth coverage of the industry with estimates & forecast in terms of volume in tons and revenue in USD thousand from 2013 to 2024, for the following segments:

By Process

- Extrusion

- Injection molding

- Blow molding

By Product

- Mechanical purging

- Chemical purging/ foaming purging

By Form

- Liquid

- Powder

- Granules

By End-Use

- Automotive

- Healthcare

- Consumer goods

- Electronics

- Packaging

- Custom molding

The above information has been provided on a regional and country basis for the following:

By Region

- North America

- U.S.

- Canada

- Europe

- Germany

- UK

- France

- Italy

- Spain

- Poland

- Benelux

- Asia Pacific

- China

- India

- Japan

- South Korea

- Thailand

- Latin America (LATAM)

- Brazil

- Mexico

- Argentina

- MEA

- Saudi Arabia

- UAE

- Kuwait

- Oman

- South Africa

Frequently Asked Question(FAQ) :

Where will global purging compound market size depict an increase?

Asia Pacific purging compound industry share may increase with a CAGR of 7% through 2024, owing to robust industrialization and composite usage across major end-use sectors.

Why will automotive sector emerge as a lucrative avenue for global purging compound industry?

Automotive sector may cross USD 130 million by 2024, owing to rising adoption of sustainable and lightweight plastic materials in the form of films, fasteners, and equipment.

Which form of purging compound is usually preferred by manufacturers?

Liquid form is usually preferred due to the fact that it is very suitable for color to color and resin to resin changes for quick and cost-effective conventional processing. Purging compound industry size from liquid segment may depict 7.5% CAGR through 2024.

How much will global purging compound market size be valued at, by the end of 2024?

Global purging compound industry size was worth USD 300 million in 2016 and may surpass 14 kilo tons by 2024, driven by shifting manufacturer preference to curb raw material wastage, lower cleaning costs, & reduce machine downtime.

Which process will prove lucrative for the industry growth?

Global purging compound market share from extrusion process may depict 7% CAGR through 2024, owing to extruded product advantages such as ease in carbon removal and faster color & material changes.

What factors will push the demand for mechanical purging compounds?

Expanding manufacturing sector and rising demand for plastic processing units will increase global mechanical purging compound market size, slated to be valued at USD 400 million by 2024.

How much size did the global Purging Compound Market register in 2016?

Purging Compound Market size was valued over USD 300 million in 2016

What will be the worth of the Purging Compound industry by the end of 2024?

The worth of Purging Compound Market is expected to reach a valuation of 600 mn by 2024.

Purging Compound Market Scope

Related Reports