Summary

Table of Content

Nickel Superalloy Market

Get a free sample of this report

Form submitted successfully!

Error submitting form. Please try again.

Thank you!

Your inquiry has been received. Our team will reach out to you with the required details via email. To ensure that you don't miss their response, kindly remember to check your spam folder as well!

Request Sectional Data

Thank you!

Your inquiry has been received. Our team will reach out to you with the required details via email. To ensure that you don't miss their response, kindly remember to check your spam folder as well!

Form submitted successfully!

Error submitting form. Please try again.

Nickel Superalloy Market Size

Nickel Superalloy Market size was USD 7.5 billion in 2019 and will grow at a CAGR of 6.7% between 2020 and 2026. Favorable trends associated with global air passenger traffic growth will generate a plethora of opportunities for aircraft parts manufacturing.

Nickel superalloy is an alloy with nickel as a principal element. Besides nickel, various metals and materials, such as iron, copper, chromium, & molybdenum, are used during the formation of these alloys. These alloys are also called high-performance alloys owing to their versatile operational characteristics. These alloys can be used over a wide range of temperatures and pressures. Furthermore, these alloys offer superior corrosion resistance and provide necessary strength.

To get key market trends

Rising oil & gas drilling activities across the globe will bolster the sales of nickel superalloys in the future. Many governments are investing huge amounts of money to accelerate the oil & gas sector growth. In 2016, China agreed to invest over USD 280 billion in Iran’s oil, gas & petrochemical sector for the next 25 years as a part of the China–Iranian investment deal. Such trends will support the nickel superalloy market expansion as the product is widely used in downhole components, tubing, pressure vessels, etc.

Nickel Superalloy Market Report Attributes

| Key Takeaway | Details |

|---|---|

| Market Size & Growth | |

| Base Year | 2019 |

| Market Size in 2019 | 7,545.8 Million (USD) |

| Forecast Period 2020 to 2026 CAGR | 6.7% |

| Market Size in 2026 | 10,450.8 Million (USD) |

| Key Market Trends | |

| Growth Drivers |

|

| Pitfalls & Challenges |

|

What are the growth opportunities in this market?

The surging population and economic development are constantly increasing the demand for energy across the globe. These power plants operate under high-temperatures, ranging from 5000C - 1,0000C, and with technological advancements to produce steam even under high-temperature limits such as in supercritical thermal plants and gas-based power plants. The factors will increase operating temperature limits in the coming years.

Power plants use nickel superalloys for several applications including the manufacturing of gas and steam turbines, heat exchangers, scrubbers, and so on. In addition, their corrosion resistance and reduced macrofouling properties also find many applications in nuclear power plants, thereby driving nickel superalloy market trends.

The prices of nickel, iron, cobalt, copper, aluminum, titanium, and other metal commodities are highly influenced by national income & population, cost & technology, government policies, weather, interest rates, and exchange rates. However, volatile raw material prices coupled with high production costs will restrain the nickel superalloy market growth. In addition, the closure of several manufacturing facilities across the globe owing to the COVID-19 pandemic will negatively influence the alloy demand across various applications for the short-term.

Despite a recent slowdown in the demand from the aerospace and power generation sectors in the backdrop of lethargic economic conditions, nickel superalloy market is likely to offer immense opportunities in the long run.

Nickel Superalloy Market Analysis

Learn more about the key segments shaping this market

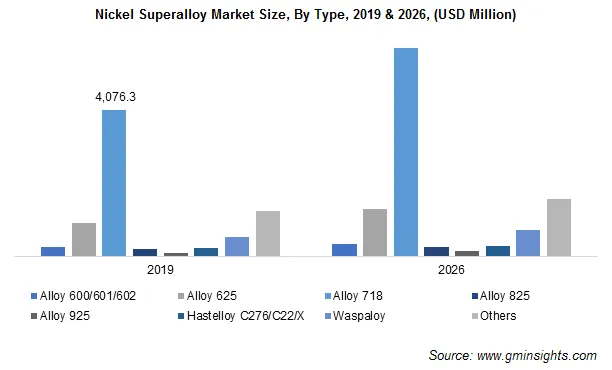

Alloy 718 is a nickel-chromium-molybdenum alloy and generated over USD 4 billion in 2019 as it provides excellent resistance against pitting and corrosive environments. The alloy offers excellent tensile strength and creep-rupture characteristics at high temperatures. The presence of niobium in the alloy aids in age hardening, thereby simplifying annealing & welding processes.

This nickel alloy can be readily fabricated and welded in either a precipitation-hardened or annealed condition. The superalloy is used in a variety of industries such as aerospace, chemical, marine, pollution-control, oil & gas, and power generation.

Learn more about the key segments shaping this market

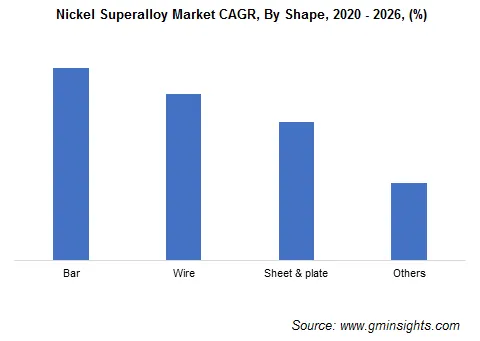

Nickel superalloys are available in different shapes, round bars, flat bars, rectangular bars, sheets, plates, wires, strips, etc. The nickel superalloy market share from bars segment will witness 6% CAGR through 2026, attributed to a wide range of applications. In aerospace, bars are used to produce shafts, gear components, struts, engine parts, etc.

Furthermore, these bars are useful in the power, oil & gas, and chemical sectors for various applications such as cryogenic storage tank components, nuclear fuel element spacers, pump bodies, wellhead parts & components, etc.

In the aerospace & defense sector, nickel superalloys are used in the manufacturing of gas turbine engine parts, turbine blades, discs, airframe components, rocket parts, etc. In 2019, the aerospace & defense sector captured approximately 40% volume share. Several developed and developing economies are investing continuously in space abilities and infrastructure to fulfill various national objectives such as development & resource management, military success & defense strategy, and leadership & prestige.

Investment in space development is a key parameter in economic growth and diversification as it enables services that boost the productivity of other sectors, i.e., right from agriculture to mining to the commerce of all types. Additionally, in 2018 alone, five new space agencies were launched globally including Luxembourg, Zimbabwe, Australia, Portugal, and Greece. The rising number of countries entering and investing in the space sector will positively influence the nickel superalloy market revenue.

Looking for region specific data?

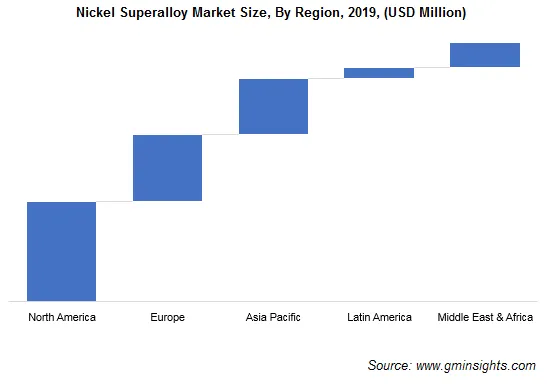

The North America nickel superalloy market will hold over 35% share throughout the study timeframe. It is attributed to increasing consumption of these superalloys in various end-use sectors, particularly from the U.S. aerospace and energy sectors. Furthermore, the inflow of investments along with the transformation and implementation of policies in the aerospace sector will drive the regional market.

For instance, in 2019, the U.S. budget allocation for the space industry was around USD 22.16 billion. Such investments in the aerospace sector will positively encourage the nickel superalloy market sales across the region.

Nickel Superalloy Market Share

The key participants in the nickel superalloy industry adopted various strategies including product differentiation & development, strategic partnerships & collaborations, and production capacity expansion to gain a competitive advantage. In July 2020, VDM Metals introduced Alloy N10675, a corrosion-resistant nickel-molybdenum alloy. This alloy offers excellent resistance against hydrochloric acid and other media in high-temperature environments.

The industry players include:

- Sandvik AB

- Aperam S.A.

- VDM Metals GmbH

- Precision Castparts Corporation

- Voestalpine AG

- Allegheny Technologies Incorporated

- Haynes International, Inc.

- Rolled Alloys, Inc.

The nickel superalloy market report includes in-depth coverage of the industry with estimates & forecast in terms of volume in tons and revenue in USD million from 2016 to 2026 for the following segments:

By Type

- Alloy 600/601/602

- Alloy 625

- Alloy 718

- Alloy 825

- Alloy 925

- Hastelloy C276/C22/X

- Waspaloy

- Others

By Shape

- Bar

- Wire

- Sheet & plate

- Others

By Application

- Aerospace & defense

- Power generation

- Oil & gas

- Refinery

- Chemical

- Others

The above information is provided on a regional and country basis for the following:

By Region

- North America

- U.S.

- Canada

- Europe

- Germany

- UK

- France

- Spain

- Italy

- Asia Pacific

- China

- India

- Japan

- South Korea

- LATAM

- Brazil

- Mexico

- MEA

- South Africa

- Saudi Arabia

- UAE

Frequently Asked Question(FAQ) :

How will the growth of global air passenger traffic influence the nickel superalloy market size expansion?

In 2019, the global nickel superalloy industry revenue valued at USD 7.5 billion and is set to grow at 6.7% CAGR through 2026 owing to increasing opportunities for aircraft parts manufacturing due to favorable trends related to the global air passenger traffic growth.

What factors of Alloy 718 will contribute to the expansion of the global nickel superalloy industry size?

Alloy 718 recorded over USD 4 billion in 2019 and its ability to provide outstanding resistance against corrosive and pitting environments along with its excellent tensile strength will fuel the industry augmentation in the coming years.

What attribute will drive the North American market share growth?

The North American nickel superalloy industry size is likely to hold more than 35% share through 2026 due to rising adoption of the superalloys in various end-use sectors along with the inflow of investments and implementation of policies in the aerospace sector.

Why will bars emerge as a profitable segment for the growth of global nickel superalloy market share?

The bars segment is expected to grow at 6% CAGR through 2026 driven by its range of applications in the aerospace industry, power, oil & gas, and chemical sectors, and more.

Nickel Superalloy Market Scope

Related Reports