Aerospace 3D Printing Materials Market worth $495mn by 2026

Published Date: June 2020

Aerospace 3D Printing Materials Market size is set to exceed USD 495 million by 2026, according to a new research report by Global Market Insights Inc. Increasing aircraft production to meet production backlog will drive the industry growth.

The aerospace industry has seen a radical shift from subtractive manufacturing towards additive manufacturing owing to innumerable benefits such as less material waste, faster turnarounds, low-volume production, complex parts production, faster prototyping and tooling, and excellent functional integration of components. These factors will drive the aerospace 3D printing materials market growth.

The U.S. leads the aerospace production and is followed by France, Germany, and Japan. The manufacturers are adopting 3D printing technology to reduce the production time. Significant product innovation in expanding the product portfolio for manufacturing aircraft parts. Moreover, positive outlook for aviation sector in the emerging economies such as China and India will drive the market growth.

Get more details on this report - Request Free Sample PDF

The tooling segment holds significant share in the aerospace 3D printing materials market as it allows more freedom to create complex parts for design and fabrication. Aerospace companies benefit from AM to manufacture custom tooling equipment such as jigs & fixtures on-demand. Also, AM enables to produce tooling faster with short turnarounds at a lower cost per part, thus driving the materials demand in tooling.

The metals segment in the market will likely register a healthy growth of over 18.5% till 2026 owing to increasing adoption of titanium and Inconel in critical aerospace applications. Ti6Al4V is predominantly used in aerospace industry owing to its high resistance to fatigue, corrosion resistant, and high strength-to-weight ratio. This aerospace 3D printing material is majorly used in fracture critical parts and structures such as complex turbine engine components, compressor blades, airframe, etc.

Browse key industry insights spread across 285 pages with 410 market data tables & 34 figures & charts from the report, “Aerospace 3D Printing Materials Market Size By Material (Plastic [Plastic Filaments {PEI, ABS, PC & Blends}, Plastic Powder {TPU, PEEK, Polyamides, PEKK}, Metal [Titanium, Aluminum, Inconel], Ceramic), Application (Rapid Prototyping, Tooling, Part Production), Aircraft Parts (Engine Components, Structural Parts, Jigs & Fixtures), By End-Use (Aircraft [General & Commercial Aircraft, Military & Defense], Spacecraft) Industry Analysis Report, Regional Outlook, Application Growth Potential, Price Trends, Competitive Market Share & Forecast, 2020 – 2026” in detail along with the table of contents:

https://www.gminsights.com/industry-analysis/aerospace-3d-printing-materials-market

The engine segment is estimated to witness around 20% CAGR during the forecast period owing to growing adoption of aerospace 3D printed materials such as titanium and Inconel in the production of critical engine components. GE9X engines comprise around 300 3D printed parts which includes fuel nozzles and turbine blades. Furthermore, growing demand for metal 3D printed parts in engine encouraged GE to print around 30,000 fuel nozzles for its LEAP engines. Each engine manufactured contains 19 3D printed nozzles which improves its fuel efficiency as much as 15%.

The spacecraft segment is projected to witness robust growth as AM plays a vital role in space industry in manufacturing critical components and spare parts for satellites and launch vehicles. Thus, increasing space exploration activities coupled with growing investments for product innovation is expected to drive the market demand.

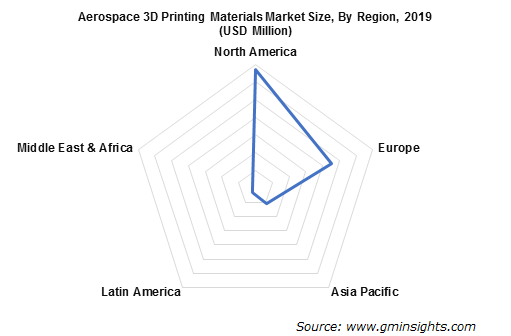

The European aerospace 3D printing materials market is predicted to dominate a considerable share of around 35% by 2026, due to strong presence of leading aerospace companies, such as Airbus. In addition, presence of additive manufacturing participants supports the regional penetration. France, UK, Germany, and Italy are the major contributors accounting for nearly 20% of total aerospace production, thus are key consumers of the 3D printing materials.

Strategies such as expansions and acquisitions are incorporated by key industry players to gain significant position in the industry. The key market participants include GE, Arkema, Stratasys, BASF SE, Ultimaker, Solvay, 3D Systems, and ExOne.

Kiran Pulidindi, Sayan Mukherjee