Summary

Table of Content

Hoist Sling Chains Assemblies Market

Get a free sample of this report

Form submitted successfully!

Error submitting form. Please try again.

Thank you!

Your inquiry has been received. Our team will reach out to you with the required details via email. To ensure that you don't miss their response, kindly remember to check your spam folder as well!

Request Sectional Data

Thank you!

Your inquiry has been received. Our team will reach out to you with the required details via email. To ensure that you don't miss their response, kindly remember to check your spam folder as well!

Form submitted successfully!

Error submitting form. Please try again.

Hoist Sling Chains Assemblies Market Size

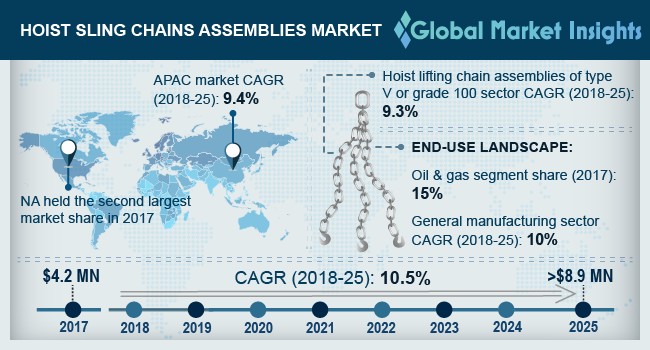

Hoist Sling Chains Assemblies Market size was over USD 4.2 million in 2017, with projected gains close to 10% CAGR between 2018 and 2025.

To get key market trends

To get key market trends

Emergence of China and South Korea as the leading force in the shipbuilding industry has been the major driver for increasing the demand for hoist sling chains assemblies in the recent decade. Increase in ship repair and maintenance activities will drive the demand for hoist lifting chains assemblies across the globe in the future years. Growing shipbuilding industry and increasing mega-ship building projects for instance, container ships such as Cosco Glory, Cosco Development by Hyundai Heavy Industries, present brighter outlook for hoist lifting chains assemblies demand in the near future.

As per a publication by the UN Department of Economic and Social Affairs, by 2030, cities having over 500,000 inhabitants will rise by 30% in Asia. Expanding urbanization and population feeding requirements in countries such as India, South Korea and Taiwan present strong growth aspects in the regional construction sector. Such trends present significant potential for the regional hoist sling chains assemblies demand over the forecast span.

Hoist Sling Chains Assemblies Market Report Attributes

| Key Takeaway | Details |

|---|---|

| Market Size & Growth | |

| Base Year | 2017 |

| Market Size in 2017 | 4.2 Million (USD) |

| Forecast Period 2018 - 2025 CAGR | 10% |

| Market Size in 2025 | 8.9 Million (USD) |

| Key Market Trends | |

| Growth Drivers |

|

| Pitfalls & Challenges |

|

What are the growth opportunities in this market?

Hoist Sling Chains Assemblies Market Analysis

Type T (or Grade 80) sling chains led the overall sling chains market in 2017 with a market share over 50%. Type T chain, with robust strength, is mainly used as overhead lifting sling component. Recommended for overhead lifting by ANSI, NACM, & OSHA, type T hoist sling chains and attachments are engineered for superior strength, durability and lightness. Standard sling configurations consist of chain branches which are affixed on one end to a master link or ring with some attachment, usually a hook, fastened to the opposite end. The industry will observe sustainable advancements by 2025 without compromising any of the characteristics required to be compliant with ASME, ASTM, ANSI, and NACM Standards.

The master link carries the chain legs and serves as the connecting point between the chain and the pulling device. In 2017, master links having load bearing capacity below 5.0 tons held a significant market share close to 30% in hoist lifting chains market. The product will be demanded especially for applications when extra strength is required, or environmental hazards such as chemicals or excessive heat are involved.

Global hoist lifting chains assemblies market will mark strong growth for hooks, with a projected CAGR surpassing 9% over the forecast period. Foundry hooks are designed with a wide, deep throat, they fit trunnions and handle on moulds or castings; these are generally used in foundry work. Grab hooks have been designed with a special narrow throat and used to shorten or hold a length of chain. Self-locking hooks are likely to witness high demand by 2025, for their higher efficiency.

North America sling chain assemblies market size is probable to grow with a CAGR of 10.6% by 2025. Hoist sling chains assemblies are preferable for lifting heavy-duty loads and in high-temperature applications. The durability and strength of these chains support their usage in steel mills, foundries, heavy machine shops, etc. Lifting chains assemblies will have strong demand in other areas involving repetitive lifts and harsh surroundings, that would damage slings made of synthetic nylon, wire ropes or polyester. Hoist lifting chains are fully repairable if are damaged and could be re-certified and load tested after repairing. With such unique traits, global hoist lifting chains industry will observe a steady demand by 2025.

Hoist sling chains assemblies assist operators in manufacturing, warehousing and construction to lift loads in support of production or storage activities, loading and unloading, or one process to the next. Oil & gas segment contributed about 15% share in the overall hoist lifting chains assemblies market in 2017. Increasing offshore drilling subject to growing crude oil demand from end use industries like refineries will augment the oil & gas sector growth in the forecast period, which in turn will have a positive influence on hoist sling chains assemblies demand.

Sling chains market was led by Asia Pacific, followed by North America in 2017, and the similar trend is expected throughout the forecast timespan. Asia Pacific sling chains market size is expected to grow with a CAGR of 9.4% by 2025. The U.S. Energy Information Administration (EIA) has estimated that the total natural gas consumption in the U.S., will upsurge to about 31.6 TcF by 2040, with 56% of this rise in natural gas production resulting from the upward development of shale gas. For the next decade North America will remain the leader in terms of growth in production of liquid hydrocarbons. The regional hoist sling chains assemblies market will witness significant demand from the oil & gas sector.

Hoist Sling Chains Assemblies Market Share

Some of the key sling chain manufacturers in the market have been:

- RUD Group

- pewag

- Gunnebo

- Peerless Industrial Group

- J.D. Theile

The market has been highly competitive with significant strategy initiatives by competitors. For instance, in May 2018, RUD Group entered into a partnership with Caldwell Lifting Solutions and combined its sales & service activities for its lifting and material handling solutions in the U.S. and Canada. This partnership will help the company to increase its market in the U.S. and Canada with a new level of expertise and a wider range of products from a single source.

Industry Background

Sling chain assemblies are the lifting media or equipment that is used directly or indirectly to connect the load to hoist chains, and which do not form part of the load. The report includes demand estimates for sling chain assemblies used in hoist only. Standard lifting sling chain consists of one, two, three and four legs, each having a hook at the end, and affixed to a master oblong link at the top. These assemblies are easy to inspect, proof-test, and re-certify if they are repaired and will have a high preference in the near future in various areas including: oil & gas, energy, metal processing, transportation, general manufacturing, construction, etc.

Frequently Asked Question(FAQ) :

Who are the leading manufacturers of hoist sling chains assemblies?

Currently, RUD Chain, Inc., THIELE, Parsons Chain China, Chaineries Limousines, FEW Ketten Walder, J. D. Theile GmbH & Co. KG, Retezarna A.S., McKinnon Chains, Peerless Industrial Group, Inc., Juli Sling Co. Ltd., and Force Chain are some of the leading manufacturers of hoist sling chains assemblies.

Why are master link assemblies recording high demand?

Master link assemblies are recording robust demand owing to its excessive strength and stress enduring capacity as well as its ability to operate with environmental hazards like chemicals or excessive heat.

Which factors are likely to boost the demand for hoist sling chains assemblies across Asia Pacific?

Rapid urbanization across countries like India, Taiwan and South Korea has generated strong growth prospects in the regional construction sector, favoring the demand for hoist sling chains assemblies across APAC.

What was the estimated global hoist lifting chains assemblies market size in 2017?

The market size of hoist lifting chains assemblies exceeded USD 4.2 million in 2017.

What is the anticipated growth for the hoist lifting chains assemblies industry share during the forecast period?

The industry share of hoist lifting chains assemblies is projected to grow at 10% CAGR between 2018 and 2025.

What are the growth prospects of hoist sling chains assemblies market?

Robust advancements in the global shipbuilding sector and commencement of mega-ship building projects are expected to endow hoist lifting chains assemblies industry with lucrative growth proceeds over the coming years.

Hoist Sling Chains Assemblies Market Scope

Related Reports